|

||

The number of farmers in Korea is rapidly decreasing. The agricultural sector is barely able to maintain its productivity due to the avoidance of agriculture, as well as the aging population and low birth rate. The number of farmers hiring foreign workers has also increased, but problems with skills and language are causing additional stress to farmers. This trend is no different overseas. Thanks to the development of robots and AI technology, various robots are entering the agricultural field. In agriculture, it is difficult to use foreign technology due to differences in agricultural products from country to country, so technology developed domestically is desperately needed. Robots using AI are being developed in advanced countries and China, but Korea is still at its infant. Meanwhile, SN Solutions, which is developing groundbreaking and practical agricultural robots, is receiving a lot of attention from the industry.

|

AI agricultural robots bring change to agriculture

From harvest time to harvesting methods

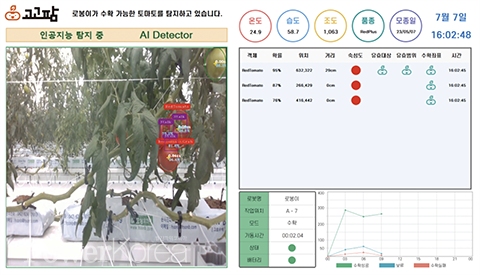

Established in 2019, SN Solutions is a company that is pioneering a new path in agricultural robots with Gogo Farm, an artificial intelligence-based multifunctional agricultural harvesting robot. Agriculture requires a lot of labor, but the profits are low compared to the effort and the labor, so many people are reluctant to do it. Gogo Farm is researching various agricultural robots with IT technology to solve labor shortage problems and difficulties that may arise in harvesting. For example, harvest robots recognize each fruit and determine its ripeness through object recognition, image collection, and AI detectors. For strawberries, tomatoes, and cucumbers, each fruit ripening during the harvest season must be individually checked and harvested every day, so farmers have no time to rest and more manpower is needed. In farms where there is a severe shortage of labor, foreign workers are replacing the labor force. They have low work skills and lack of responsibility, so they harvest products that are not yet ripe or harvest them in the wrong way, leading to a decline in quality. For high-income fruits and vegetables, harvesting, sorting, and packaging take up more than 50% of total working hours. Naturally, the intensity of labor is high and this is the field with the highest dependence on foreign labor amidst the current agricultural population shortage.

|

Gogo Farm’s automatic harvest robot ‘Bongbongi’ is evaluated as a solution that can fundamentally solve this problem. ‘Bongbongi’ can only harvest fruits with over 90% ripeness recognition rate based on real-time video and environmental information through artificial intelligence. The maturity level is classified through color and brightness values, and the LED brightness can be adjusted to the set Lux value during night work, so it can be performed both day and night. To prevent a decline in marketability, technology for harvesting while preserving the fruit’s top was also applied, making it possible to supplement the harvesting labor situation.

|

Versatility from drive to joints

Autonomous driving, image collection and labeling

Due to the topography of Korea, there are not many wide plains, so farming is often done intensively in small areas, and the seasonal changes are extreme, so the environment today is different from yesterday. Gogo Farm manufactured the robot joints into a multi-joint type to ensure versatility even in these situations. Skara is characterized by its compact structure and the ability to work quickly and accurately. However, because the structure is compact, the driving range is small and it is limited by the environment. However, ‘Bongbongi’ is a multi-joint system that has a wide operating range and can be applied to a variety of environments. It can be applied to various crops by replacing the end effector. ‘Bongbongi’ is operated by performing a mapping process to create and input a route, and notifying the manager when an obstacle occurs in the driving route. ‘Bongbongi’ has various other functions such as image collection and labeling, so it can be operated in any environment.

|

| ▲ SN Solutions / CEO Wonsuk Ko |

Automatic harvesting robot ‘Robongi’, automatic mowing robot ‘Dabear’

Exhibited in the AgTech Zone at the 2023 K-Farm Expo

‘Bongbongi’ is conducting a cherry tomato demonstration project at the Smart Farm Innovation Valley in Sangju, Gyeongsangbuk-do, and plans to launch a greenhouse product in January next year. ‘Bongbongi’ has only the functions essential to farming, reducing production costs and increasing practicality. The company is conducting cost-saving research, and Gogo Farm is expected to increase people’s access to innovative agricultural technologies and resolve the shortage of harvesting personnel through ‘Bongbongi.’ Gogo Farm recently developed a wireless autonomous mowing robot called ‘Dabear’ and launched it in April. It can be operated in various places such as orchards, mountainous areas, graves, etc., and weeding can be done remotely. This improves the low drivability of existing lawn mowers, produces various blade widths, and can adjust the height from 2 to 15 cm, so it can be used in various environments and for various purposes. In addition, this can be controlled from a distance of 200m using a drone controller, allowing for convenient mowing. Gogo Farm introduced these robots at the BETA Festival 2022 and 2023 K-Farm Expo, receiving great interest and response. In particular, they were displayed in the AgTech Zone at the 2023 K-Farm Expo and were recognized as cutting-edge technology.

신태섭 기자 tss79@naver.com