|

||

As the number of smart factories increases, so does the concern about breakdowns. Due to the nature of smart factories that operate organically with each other, the failure of any one of them can cause the factory to stop, resulting in huge financial losses. Therefore, it is important to build a smart factory, but it is also necessary to build a way to predict and prevent accidents or incidents in advance.

Predictive maintenance, for this reason, is gaining attention. Predictive maintenance is a technology that analyzes vibrations or currents to determine if something is wrong with the equipment. Just as your body gives you warning signs like fever or pain before you get sick, any machine will give you warning signs like vibration or current before it starts to have problems. Predictive maintenance is about identifying abnormal signals and looking at the overall health of a machine so that you can make repairs before it malfunctions or breaks down. The predictive maintenance market is growing with the increase in smart factories. It was worth $1.4 billion in 2016, but is expected to grow at an average annual rate of 39% to $28.1 billion in 2026. Intellectual Technology Space is a company that is gaining attention for applying smart technology to such predictive maintenance technology. The company has developed UYeG-SE, a predictive maintenance solution that reduces maintenance costs and increases management reliability. Monthly PowerKorea met CEO Youngkyu Lee and learned its innovative technologies.

|

Solutions for an era where energy is a resource

YUeG is an optimum solution for smart MCC

Intellectual Technology Space has developed WINDOWBASE S/W and MICOM application H/W S/W. The company provides various industrial automation and information and communication solutions such as performance testing, data analysis, production status, noise and vibration monitoring and analysis, and vision analysis and control.

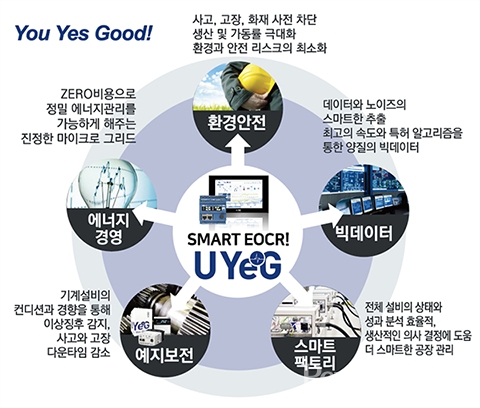

UYeG, developed by the company, is a predictive maintenance system solution that can prevent smart factory equipment failures and accidents in advance. CEO Lee says “The Fourth Industrial Revolution is when data becomes a resource like oil or gold.” Manufacturing industry and information and communication technology are converging to enhance production competitiveness. A smart factory must manage productivity, such as quality analysis, detection of defect causes, facility status, predictive maintenance, and lifetime prediction, as well as fire, accident, and failure management. For this, Intellectual Technology Space has developed UYeG, a system for zero downtime with higher productivity, uptime, and safety.

UYeG is a solution that prevents accidents by measuring and monitoring the current, voltage, power, harmonics, leakage current, and temperature and humidity of the motor inside and outside the plate. Optimized motor protection with various protection methods and a wide current range, and the addition of protection against high fault currents makes it the optimal solution for smart MCC implementations that can manage motors more reliably.

|

More features for smart MMC implementation

Applied for 387 patents in the process of implementing the visualization algorithm

UYeG is equipped with various functions for smart MMC implementation that reliably manages motors: monitor active and reactive power and wattage - Three-phase current measurement, time limit, half-time limit, and heat accumulation half-time limit protection.

As for the protection function, it protects all power elements such as overcurrent, undercurrent, phase, reverse phase, stray current, overvoltage, undervoltage, voltage phase, overpower, and low power factor, and the operation time can also be set, so you can have a safety system according to the factory. The company has implemented specialized algorithms for such surveillance and has filed 387 patents in the process. CEO Lee says “We have algorithms that filter out what’s moving and what’s not moving, and we can see it in the data.” It can communicate up to 200 meters and can set and store the date, time, and driving time, which can be used to determine the circumstances of a breakdown or accident and serve as data for future use.

Other features include analog input of vibration, pressure, flow, distance, gas, and environmental sensors, and you can set a password for security.

|

Combining various sensors and AI to increase utilization

Certified for direct production of public innovation procurement products

Intellectual Technology Space integrated a power meter into the UYeG and developed it into a single device. The result is the UYeG-SE, which monitors three-phase and single-phase power with 1% precision, while also providing high-speed harmonic analysis of motor current and voltage up to the 51st order for predictive management of the monitor’s health and condition. For communication, Modbus TCP/IP provides speeds of 100/10 Mbps, as well as Daisy chain technology, which makes it easier and faster to combine devices. You can also connect various sensors that support Current Loop to collect data remotely and report it as a contact output.

These UYeG solutions incorporate AI artificial function technology to select and learn AI models, verify model performance, and retrain them to provide statistical analysis, prediction, and analysis reports.

Reports are particularly useful because they can organize and visualize this by time period and extract key statistics from anomalies and failure patterns.

|

| ▲ Intellectual Technology Space / CEO Youngkyu Lee |

UYeG SE is versatile and affordable enough to be applied to any size and type of factory. A company official says “It can reduce costs by more than 1/40th compared to traditional vibration analysis predictive maintenance techniques, and is applicable to all equipment and industries that use motors.” UYeG SE is compatible with traditional industrial devices and records fault waveforms to improve the reliability of motors in industrial sites, as well as to enable efficient maintenance, reducing the cost of maintenance and repair.

UYeG has been certified for direct production of public innovation procurement products, and CEO Lee expressed his ambition: “Through predictive maintenance, we will eventually grow into a company that identifies and protects the happiness of families and the safety of people.”

신태섭 기자 tss79@naver.com