|

||

Environmental pollution caused by waste plastic is at a serious level. While the counterattack of microplastics is rapidly progressing, the need of accelerating the global movement away from plastics is widely agreed and being practiced. Amid this movement, DouY’sChem, a venture specializing in nanomaterial development and production, is receiving extraordinary attention. CEO Seo Young-soo is a professor at the Department of Nanotechnology & Advanced Materials Engineering at Sejong University. DouY’sChem was established to effectively reduce the increasing amount of plastic waste every year alongside producing recyclable nanomaterials.

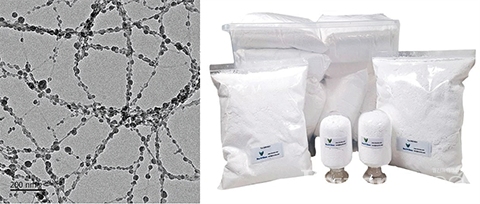

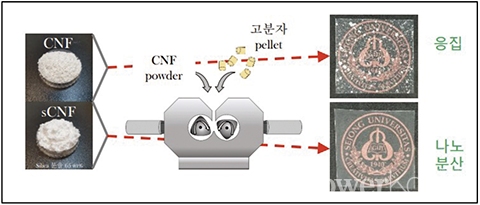

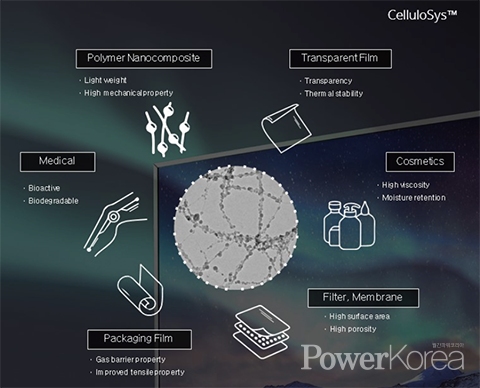

Based on the R&D capabilities accumulated over 16 years in the Department of Nanotechnology & Advanced Materials Engineering, the company secured the original technology for high dispersion and mineralization of CNF (Cellulose Nano Fiber) and created CelluloSys™, a mineralized CNF (mCNF) material. This technology can also be applied to micro-diameter cellulose, and patents have been obtained in Korea (7 cases) and in the US and Europe (1 case each). CelluloSys™ can be realized as a high-functionality and high-content polymer composite, so it is highly differentiated from existing CNF materials.

|

Nation’s first nano cellulose-driven product development

From automotive interior materials and packaging/optical films to cosmetics and paint applications

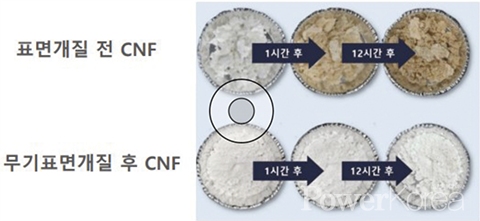

CNF materials are biodegradable, environmentally friendly, and have high mechanical strength. However, when a polymer composite material is applied, it is difficult to disperse due to low compatibility with the compound, discoloration when heated at a high temperature, and a decrease in strength, which makes it impossible to recycle. On the other hand, CelluloSys™ improved the technical problems and shortcomings that CNF materials had to solve during the development process. CelluloSys™ is harmless to the human body and environmentally friendly by using alcohol and water in the manufacturing process. It has excellent resistance to thermal oxidation and heat resistance, and prevents discoloration by blocking thermal oxidation through inorganic surface modification during the high-temperature (250﹎) compounding process.

Since there is no change in dispersion, color, and mechanical strength even after recycling more than 6 times after compounding, it can contribute to reducing the amount of waste plastic. In addition, it has unique characteristics such as high eco-friendliness by reducing the amount of plastic, excellent biodegradability and biocompatibility, and exhibiting functions such as thickening, moisturizing, and gas blocking.

|

CelluloSys™ is biodegradable, lightweight and similar in strength to glassy carbon fibres, making it the next generation of plastic reinforcement. It can be widely applied to new fields alongside the products using plastics such as reinforced plastics, automobile interior materials, packaging/optical films, medical supplies, and home appliances.

DouY’sChem is actively testing prototypes in battery separators, automobile interior and exterior materials, and functional cosmetics in cooperation with its client companies. Applied to various industrial polymers such as polypropylene (PP) and high-density polyethylene (HDPE), it is highly dispersed without aggregation, and the effect of improving the melting point, tensile strength, elastic modulus, and storage elastic modulus is remarkable. After competing the tests, therefore, mass production will be pushed forward while necessary facilities are being built at the moment.

|

Establishing a virtuous cycle of plastics with unrivaled polymer nanocomposite technology

“We will change the game of the global eco-friendly nanomaterial market”

DouY’sChem is also focusing on the development of QD (Quantum Dot) Capsule™, which is used in high brightness display, high color reproducibility and smart farm LED lighting.

This capsule stably collects QDs (quantum dots) between the polymer crystal plates and protects them from the outside. It is expected to be stably used even in the thermal processing extrusion process and can replace expensive barrier films.

DouY’sChem was recognized for its excellence in CNF and QD capsule development technology with which the company listed name in Seoul Technology Commercialization Support Project, Ministry of SMEs and Startups’ Purchase-Based New Product Development Project, Ministry of Trade, Industry and Energy’s Nano Fusion Material Technology Development Project, Gyeongbuk Center for Creative Economy & Innovation’s Startup Support Project, Corporate Affiliated Research Institute R&D Support Project, Gwangju Center for Creative Economy & Innovation’s Startup Support Project, and Seoul Technology Commercialization Support Project.

|

The company has announced its ambition to become a game changer in the eco-friendly nanomaterial market through the development of new eco-friendly materials that will reduce petrochemical-based plastics through the company-affiliated research center. DouY’sChem plans to achieve its primary goal of 5 billion won in sales by 2026 with CelluloSys™. Starting this year, the company plans to attract national research support projects by receiving investment from venture capital institutions. It also has an ambitious goal to change the global material market by listing on the KOSDAQ in 7-8 years and to expand through affiliates.

CEO Seo Young-soo is the best expert in the field of nano materials in Korea. He listed name in the winners of the 2022 Korea Value Management Awards and the 2023 Brilliant People & Brand Awards. He points out “In order to compete in technology with American, Japanese, and German companies that have enjoyed the status of a material powerhouse for over 100 years, the government’s institutional and economic support must be solidly provided.”

원헤레나 기자 hywon65@gmail.com