|

||

Due to the 2016 Gyeongju earthquake and the 2017 Pohang earthquake, the need for earthquake-resistant design of buildings is increasing. In March 2019, the Ministry of Land, Infrastructure and Transport enacted and notified relevant laws through [Seismic Design Standards for Buildings]. Existing lightweight steel frames for indoor ceiling construction have problems in installing, repairing, and managing various mechanical facilities and equipment like spider webs in the ceiling, and economic costs are wasted. In addition, safety accidents frequently occur because complex ceiling structures are installed separately or existing lightweight steel structures are used as they are. In the midst of this, Gong Gan Tech CEO Jeong Min-si drew attention by introducing earthquake-resistant lightweight steel frames that improved safety, functionality, and efficiency by improving existing lightweight steel frames that were vulnerable to vibration and sagging ceilings caused by loosening screws.

|

Anti-seismic design prevents loosening from vibration

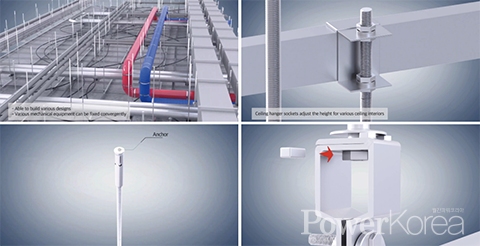

For the earthquake-resistant lightweight steel frame system, structural improvement was carried out to increase the utilization of space in the ceiling, and earthquake-resistant technology was applied to prevent screw loosening from earthquakes and various vibrations at industrial sites. In addition, in order to improve workability, the number of parts and the procedure for fastening parts were reduced, and it was developed to facilitate the installation, maintenance, and management of various mechanical facilities and equipment in the ceiling and supporting the load of workers so that complex fixation of various mechanical facilities and various ceiling design construction are possible. Gong Gan Tech’s earthquake-resistant lightweight steel frame system, therefore, is a modern lightweight steel frame system with improved functionality, workability, safety, and earthquake resistance. The construction procedure simplifies the assembly process and proceeds with anchor construction → shear bolt attachment → control hanger attachment to the kerring hanger → insertion of the kerring hanger into the carrying bar → attachment of the control hanger attached to the computerized bolt → height adjustment with the control hanger → attachment of the seismic pin.

|

The new system introduced by the company has added functionality to reflect the changing trends of the times. For example, the company developed parts that can be used selectively as needed, such as fixing various mechanical equipment in the ceiling and constructing work passages for workers. Above all, what is noteworthy is that the efficiency of installation, maintenance, and management of the in-ceiling mechanical equipment system has been greatly increased. That is, it was developed so that there is no problem from weight or vibration even if the worker steps on the structural bar supporting the load of the ceiling structure.

지윤석 기자 jsong_ps13@naver.com