|

||

From manufacturing to construction, all in one ‘30MW Smart Factory Module Line’

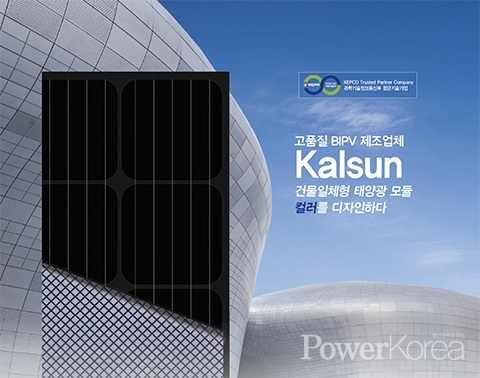

Becoming a leading company in the domestic BIPV market

Established in 2017, Kalsun is a manufacturer of explosion-proof aviation barrier indicators and solar module related products based on the values of customer first, professionalism, innovation, ownership, pride, and win-win. In recent years, the company has been leading the domestic BIPV market by securing top-of-the-line facilities and excellent technology through aggressive investment and long-term research and development.

‘BIPV’ stands for ‘Building Integrated Photovoltaic’. It is used instead of the exterior materials of the building, so that the building itself becomes a solar module and generates electricity. BIPV is different from conventional solar power. This is an eco-friendly distributed power system that reduces construction costs because there is no loss of transmission and distribution as the electricity demand and production site are the same, and the building material itself acts as a photovoltaic power generation system. Thanks to these advantages, it is attracting attention as the most important business area in the zero-energy building policy that the government is actively pursuing recently.

One of the reasons why BIPV is attracting attention is that it is a building material with high aesthetic functions, not only for eco-friendliness and economic reasons. Since BIPV itself is used as a building material, it does not need to be installed separately, so there is no sense of unity depending on the uniformity and location of the building, and it can be used as a building design element to increase aesthetics.

Kalsun customizes BIPV modules and provides them in the size desired by customers. The company has built an all-in-one ‘30MW Smart Factory Module Line’ from BIPV module manufacturing to construction. In order to secure the foundation to quickly respond to customer needs and market trends, it also has a stable workforce composition by combining manpower with core competencies. Recently, the company has introduced equipment that can solder from M6 to M10, and can conduct power generation efficiency and defect inspection of solar modules up to 2500m products.

|

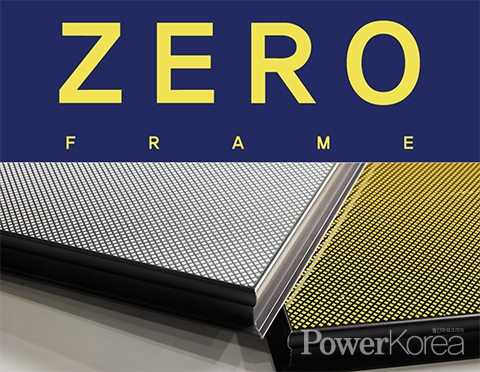

KALSUN ZERO FRAME where the frame is not exposed at all after construction

‘Z-bar’ with easy BIPV front attachment is extremely durable and safe

Kalsun has a wide range of excellent technologies related to BIPV. Among them, the most representative technologies are the ‘KALSUN ZERO FRAME’ method, the ‘Z-Bar’ method that makes it easy to request BIPV in front, and the use of ceramic dots.

Zero Frame is not exposed at all after construction. When the frame is exposed, not only the aesthetics of the building decrease, but also pollution such as rainwater, snow, and fine dust occurs, and the power generation efficiency decreases. CEO Ahn Yong-jin says, “The existing construction method had a frame exposure of up to 40mm. But Zero Frame exactly leaves glass only after finishing, and the frame is not exposed to the outside at all.”

‘Z-bar’ is a method that is easy to attach to the front of BIPV. The Z-bar, which is an auxiliary frame for insulation, can also be used as a base material for installing internal airtight and moisture-proof paper, and is fixed with a screw using an impact screwdriver to the fixed structure (steel frame or C-section steel, etc.) installed at the module installation site, and then filled with backup material again and closed with a weather seal. Compared to the general attachment method using conventional double-sided tape and silicone, this method is very durable and safe.

|

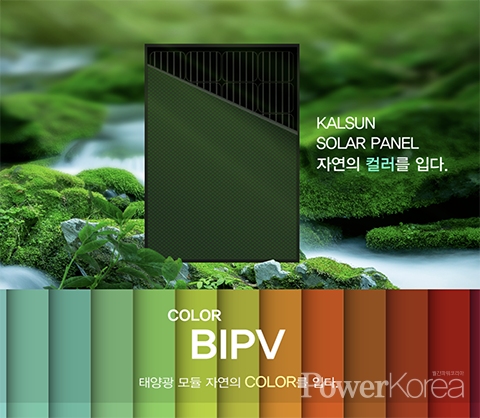

Ceramic dot coating makes colors more vivid and prevents glare

‘IBC cell’ that bends up to 20 degrees is applied, up to 3m in size and weight is reduced by 1/3

It is also worth noting that BIPV was coated with ceramic dots and IBC cells were used. When ceramic coating is applied, the BIPV color is very vivid, so when used in color products, the effect can be higher, and the glare phenomenon can be prevented because the light reflection is small.

IBC cells do not have poles in front and have a very high tension compared to ordinary cells. Therefore, there is no damage due to any degree of bending. Ordinary cells are like thin glass, and when bending occurs, the cells inside will break, and eventually the power generation efficiency will be lowered. However, IBC cells are very safe because they do not break even if they are bent up to 20 degrees. Ahn says, “Recently, large BIPV modules installed in skyscrapers are very large, heavy, and have to be moved by humans, so they are easily damaged in the process, and such damage can be prevented.”

Kalsun has also recently developed an all-in-one solar module. It can be manufactured up to 3 meters in length and is very suitable for use in high-rise buildings. Usually, the 1m*2m large module, which is often used in high-rise buildings, weighs up to 100kg, which is difficult to transport for installation, and there is a great risk of damage in the process. To compensate for this shortcoming, the company attached Honeycomb to the glass, reducing the weight by one-third. Honeycomb has great strength and smoothness, so it is often used for building exterior materials and airplane materials. This product has passed KS Certification, Building Material Certification, seismic test and sound insulation test, and has also obtained the Hazardous Substance Restriction Directive Certification. The company plans to receive Excellent Product Certification within this year and register to the Public Procurement Administration. Ahn says, “The module with a Honeycomb panel applied to the back of the module minimizes the thickness of the glass applied to G to G, making it possible to reduce the weight by 30%, which is a disadvantage of the existing G to G module. This also differentiates it from glass BIPV in terms of ease of installation and transport, and enables robust installation with high strength and wind pressure resistance.” Kalsun’s dry method is a method that uses a specially made frame and clamps to fix it without using silicon or concrete, and it is also a patent-applied method. In this method, the unit module is supported by clamps, so the load on the upper part is not transferred to the lower part, and a space is formed at the back of the module to reduce the heat flow effect, thereby increasing the insulation effect and preventing condensation inside the wall to a certain extent. This method is also made up of unit modules, which makes the renovation work easy, the construction fast and simple. Kalsun’s excellent technology is widely recognized. It is planned to be installed in the data center of Korea Electric Power Corporation, and has also been installed at the Eum Center in Namwon, North Jeolla, and various educational institutions nationwide.

|

Installation in aviation obstruction lights, Incheon Airport and Baccarat Nuclear Plant in UAE

Kalsun is a company with a long history and expertise in aviation obstacles. Aviation obstruction lights are lighting devices to signal the presence of buildings or dangerous objects that are likely to obstruct night aviation, and are important devices that allow pilots to avoid them. The absence of this aviation obstruction light is an essential tool for safe aviation, as a helicopter crashed into an apartment building in 2013.

The company provides a variety of aviation obstacles, and has secured excellent technology in the field of explosion-proof aviation obstacles. Explosion-proof aviation obstacles are products installed in places exposed to environments with a high risk of explosion, such as petroleum or chemical plants, and are intended to prevent secondary explosions where internal explosions lead to external explosions. The company has obtained IECEx, ATEX, INMETRO Explosion-proof Certification, KCs Safety Certification, and satisfied the optical requirements of ICAO.

In addition, the company provides a variety of products for aviation safety, such as solar-powered LED aviation obstruction indicators, aviation obstruction indicator aids, runway temporary closure guidance visual aids, and even heliport systems. In the case of explosion-proof landing zones used in helicopter takeoff and landing strips, LED lenses are used to prevent glare, which are highly safe enough to be installed at UAM hydrogen refueling stations. Kalsun’s aviation obstacle lights have been registered as trusted items by Korea Electric Power Corporation and Trusted Partner in recognition of their excellent technology and stability, and are installed in various places, including Incheon International Airport Corporation. In addition, the Baccarat Nuclear Power Plant in the UAE, built by Korea Electric Power Corporation, is also equipped with explosion-proof aviation obstruction lights, and its excellent technology is recognized both domestically and internationally.

The company has completed the development of Touchdown Circle Lighting, an explosion-proof circle light, and Helideck Floodlight, an explosion-proof floodlight, in its own development laboratory, and will launch them in October this year. Kalsun, which has developed a variety of products based on its excellent technology, has been designated as an Energy-specialized Company, Jeonnam Star Company, and High-tech Company, and won the gold prize at the 2021 International Exhibition of Invention Geneva.

Ahn says, “Currently, we have the facility to produce 40 megabytes per year on our own. In preparation for the growing BIPV market, we intend to introduce additional BIPV automation lines within two years and actively respond to them. We aim to list the company in Konnex this year and in KOSDAQ within 3 years.”

신태섭 기자 tss79@naver.com